-

Aug 07 20192019

Intercal d.o.o.

Kiln “Number 1” goes back into operation after 9 years. Demand for dolomitic lime has risen to such an extent that kiln number 3 has reached the limits of its capacity. In combination with kiln number 3, which is currently in operation, Intercal has a capacity of 380 t/d at the site.

Aug 07 20192019IGM

IGM Zagorje secures its raw material reserves by acquiring Apnenec d.o.o. with a stone processing plant and a large, high-quality limestone quarry near Zidani Most, approximately 20 kilometres from Zagorje.

Aug 01 1982Jul 01 19822012Kamen Sirac

Intercal and LTV are merged to form Intercal d.o.o. der Kamen Sirac in Intercal d.o.o.Jun 01 19822010/11Peggau

New hydration plant commissioned and w&p Kalk GmbH founded in 2011. A few years later, it will be the parent company of the three lime companies within the Wietersdorfer Lime Business Segment.May 01 19822008Peggau

Wietersdorfer re-enters the lime production sector in 1993, with the acquisition of the Steirische Montan Werke (owner Perlmooser AG), albeit on a modest scale. Wietersdorfer returns fully to the lime business in 2009 with the construction of a new energy-efficient Maerz PFR (parallel flow regenerative) lime kiln.Apr 01 19822006Kamen Sirac

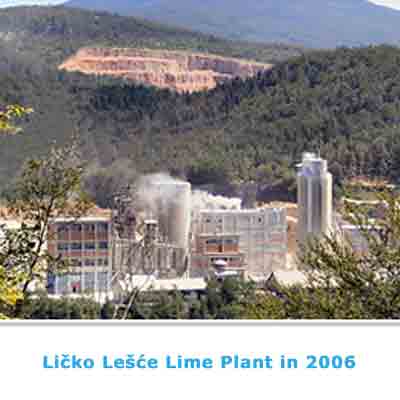

Kamen Sirac d.d. acquires Kalcind d.o.o. from Industrograd, who sells the plant to Licka Tvornica Vapna. The lime business in the Intercal Group operates under the management of Kamen Sirac. In 2009, two lime kilns are shut down at the production sites in Ličko Lešće and Sirac. The second kiln in Sirac is shut down in 2010.Mar 01 1982Feb 15 19822004Intercal

Lime kiln 3 is completed with a capacity of 200 t/d.

Feb 01 19822002Kamen Sirac

The local Chamber of Commerce of Bjelovar-Bilogora ranks Kamen Sirac d.d. as the top successful company in the medium-sized company category. The Ministry of Economic Affairs awards Kamen Sirac the title of the most successful exporter in its category.Jan 01 19822001IGM

Privatisation of IGM d.d. is completed and Salonit Anhovo, a subsidiary of the Wietersdorfer Group, takes over the company. The Lipovica quarry, which is part of IGM, is also divested.Dec 01 19812000Kamen Sirac

Kamen Sirac increases its focus on export. New markets are opened up (Slovenia, quicklime; Bosnia & Herzegovina, hydrated lime) and Kamen Sirac becomes the first Croatian building materials company to be certified in accordance with ISO 9001. In 2001, the export ratio reaches 60%.Oct 01 1981Sep 01 19811995Kamen Sirac

In 1995 the decision is made to switch from calcitic limestone to dolomitic limestone; new excavation sites are developed.

A number of modernisation measures are taken in the following years. Warehouses are also built in order to guarantee customers better and consistent product quality on the one hand and to meet technical and legal standards on the other.Aug 01 19811993Kamen Sirac

KAMEN IGM becomes Kamen Sirac d.d., war damages are repaired, production and market activities are resumed.Jun 01 19811981Kamen Sirac

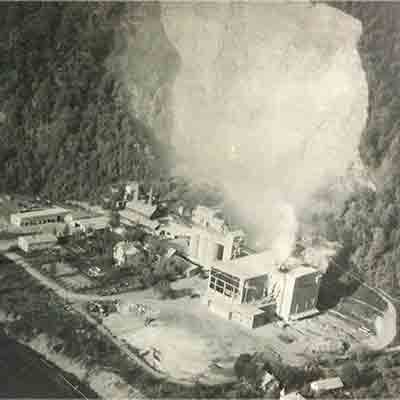

This year sees the opening of the state-of-the-art plant with its two lime kilns, each with a capacity of 175 t/d. Capacity is designed for 100,000 metric tonnes of quicklime. In addition, the company invests in a hydration plant and a bagging unit.May 01 19811970-1980Kamen Sirac

Construction of the Ličko Lešće lime kiln with a capacity of 175 t/d in the Ličko Lešće quarry. The Cardak quarry is opened.Apr 01 19811976IGM

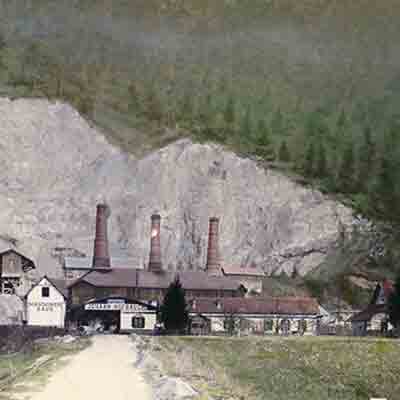

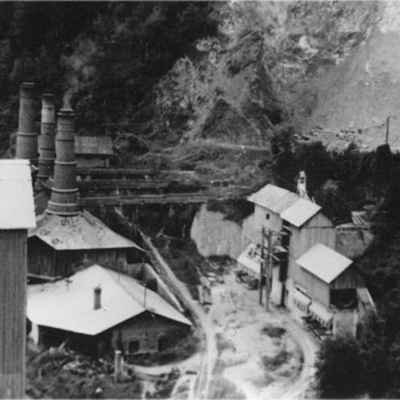

Construction of a kiln with a capacity of 300 t/d and simultaneous shutdown of 6 old kilns.Mar 01 19811961IGM

Construction of a hydration plant and (thermal) modernisation of the existing plant in the following years (annular shaft kilns, each with a capacity of 150 t/d).Feb 01 19811960Kamen Sirac

Mining and production are implemented using very simple methods until the 1960s. Drilling, blasting and dismantling are largely carried out by hand. The use of machines does not become established until this decade.Jan 01 19811958IGM

With the purchase of two Wienerberger kilns and the Kisovac cement plant, IGM becomes the largest lime producer in all of former Yugoslavia.Dec 25 19801955Intercal

The factory belonging to the Cop family is nationalised and a larger coal-fired lime kiln is built.

Dec 01 19801949Peggau

The Alois Kern company leases the factory (purchased in 1958) and initiates the expansion of the plant into a modern cement plant after only six months. The lime shaft kilns are closed in 1956 and lime production ceases.Nov 01 19801945-1948Peggau

As “German Property”, the plant is now run in public trust as a crushed stone and standard quicklime plant..Oct 30 1980Page load link1945Intercal

The Čop family establishes a lime plant on today’s Intercal site near Sirac.

Oct 01 19801937-1948IGM

Lime is burnt in four shaft kilns until nationalisation in 1948. During this period, cement is also produced in nearby Kisovec. In 1948, the two Business Segments are merged under the name IGM (Industrija Gradbeni Materiali).Sep 01 19801938Peggau

Engineer Emil Mohn buys the entire plant and launches the expansion of the plant for cement production. In addition to two cement shaft kilns, he also invests in a mill with a capacity of 12 metric tonnes per hour. As of 1942, the plant is used as an arms factory.Aug 01 19801929Peggau

The plant facilities are acquired by the engineer Otto Müller. The new owner attempts to establish cement production in addition to lime burning. However, the raw material proves to be unsuitable for cement production and it is not possible to produce standardised cement. The workforce comprises between 20 and 30 employees, depending on turnover.Jul 01 19801928Kamen Sirac

A corporation (further details are not known), which has already been active in mining crushed stone, begins lime production during this year.Jun 01 19801900IGM

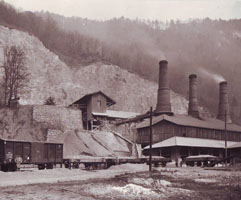

Lime production enjoys a veritable boom in the first decades of the 20th century. Several kilns are built using different construction methods, but efficiency is still low. It takes 8-10 days to burn a single batch of lime. Thanks to the large lime pieces, the quality is very good, economic viability less so.May 01 19801900Peggau

Two more shaft lime kilns go into operation, tripling the daily output. 90% of the work is still done by hand, from extraction to transporting the limestone to loading it into the kiln.Apr 01 19801893Peggau

Johann Hofbauer establishes a quarry in today’s Peggau plant and builds the first shaft kiln for lime production in 1895. In the late 19th century, limestone is mainly used for road and railway construction. The first lime kiln produces only 15 tonnes/day.Mar 01 19801889IGM

Documents indicate that 13 lime kilns produced lime to meet local demand and for export.Feb 01 19801878Kamen Sirac

No information is available on the beginnings of limestone mining at Sirac. Mining has been carried out on a regulated, semi-industrial level since 1878.Jan 01 1980Go to Top